LAB-GROWN BURGERS MAY HIT SHELVES NEXT DECADE

Posted in News, Science & Research, Beef, Meat Products, Processed Meats, Technology,Sustainability, Agriculture, Consumer Preference, Taste, Texture, Flavor, Economics, Retail, Foodservice,Processing, Fats/Oils, Proteins, Market Trends

LONDON—Scientists created the world's first test tube burger from lab-produced meat, which was cooked and sampled by two volunteers in London.

The 5 oz. patty cost about $330,000 to produce, as reported by NBC News, and medical physiologist Mark Post has been working to develop the product since 2008. Post said these artificial meat products could appear in supermarkets in 10 to 20 years.

Artificial meat production could help eliminate the need to slaughter animals, but Post's method still requires cattle for stem cells and fetal calf serum to feed muscle cells. The cells can be extracted from live cattle during a biopsy, and one sample yields 20,000 tons of cultured beef. Post's process of creating the artificial meat involves growing extracted cells into strands of muscle tissue, and it takes about 20,000 strands to create one hamburger.

With consumers' growing sustainability concerns and high beef prices driving people to consider alternative meat options, this new method of meat production could be a hit among food industry consumers.

However, the beef patty still needs some work on its flavor characteristics. According to volunteer taste-testers, the artificial meat maintained a pleasant texture, but the absence of fat made the taste less enjoyable.

To gain a deeper understanding of today's protein trends, view the Food Product Design slide show "The Changing World of Meat."

The 5 oz. patty cost about $330,000 to produce, as reported by NBC News, and medical physiologist Mark Post has been working to develop the product since 2008. Post said these artificial meat products could appear in supermarkets in 10 to 20 years.

Artificial meat production could help eliminate the need to slaughter animals, but Post's method still requires cattle for stem cells and fetal calf serum to feed muscle cells. The cells can be extracted from live cattle during a biopsy, and one sample yields 20,000 tons of cultured beef. Post's process of creating the artificial meat involves growing extracted cells into strands of muscle tissue, and it takes about 20,000 strands to create one hamburger.

With consumers' growing sustainability concerns and high beef prices driving people to consider alternative meat options, this new method of meat production could be a hit among food industry consumers.

However, the beef patty still needs some work on its flavor characteristics. According to volunteer taste-testers, the artificial meat maintained a pleasant texture, but the absence of fat made the taste less enjoyable.

To gain a deeper understanding of today's protein trends, view the Food Product Design slide show "The Changing World of Meat."

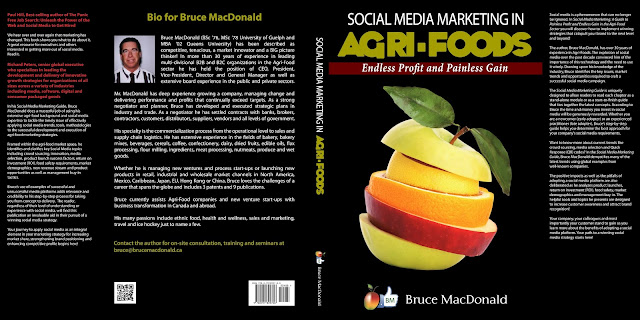

Check out my latest e-book entitled: "Social Media Marketing in Agri-Foods: Endless Profit and Painless Gain"

The book is available on Amazon and Kindle for $4.99 USD. Visit amazon/Kindle to order now:

http://www.amazon.ca/Social-Media-Marketing-Agri-Foods-ebook/dp/B00C42OB3E/ref=sr_1_1?s=digital-text&ie=UTF8&qid=1364756966&sr=1-1

Thanks for taking the time!

No comments:

Post a Comment